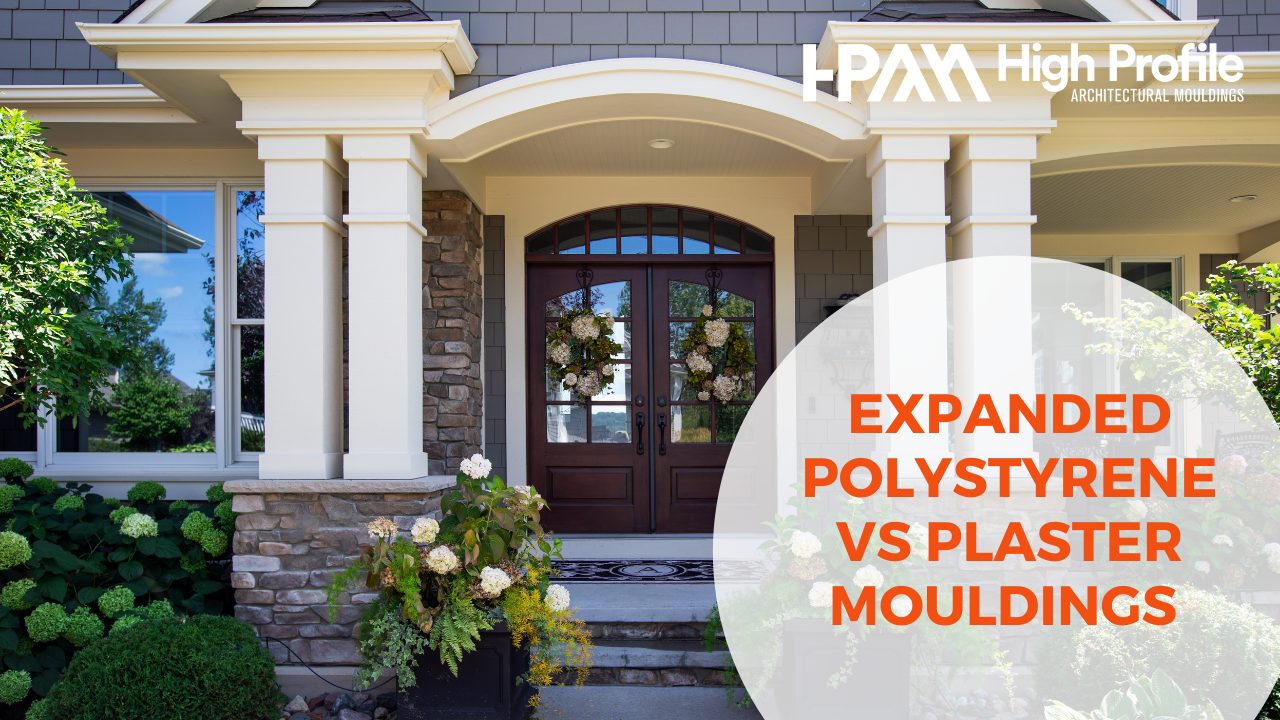

When it comes to exterior architectural mouldings, there are an abundance of materials to choose from for your build. Today we are going to talk about two materials, commonly used for exterior mouldings being plaster and expanded polystyrene.

Weight

When deciding on the right material for your build, the weight is a key factor that should be considered. Plaster has a very heavy structural weight which can create a range of problems. First of all, its heavy weight means that often, reinforcements must be added to the home in the areas where the moulding is to be installed. The weight of plaster also makes the installation process much more difficult as more manpower and time is required. Unlike plaster, expanded polystyrene (EPS) is a lightweight material that requires no additional structural support and is approximately three times faster to install.

Durability

Another key factor that should be considered when deciding on which material is the best option to use for your homes exterior mouldings is durability. If you live on Australia’s east coast you would be well aware of how harsh weather conditions can be. The summers are hot, the storms are wild, and the rain can be torrential. This means that any structure of your home’s exterior must be durable enough to withstand these conditions. Unfortunately, plaster is often very fragile and can break easily. For instance, if excessive moisture is left inside plaster when the moulding is being formed, the strength can be compromised meaning it can easily crack. EPS on the other hand is a highly durable material and can endure the harshest weather conditions. One of its many benefits is its high shock absorbency. Expanded Polystyrene is virtually indestructible, and temperatures don’t make much of an impact on its structural integrity either. EPS will maintain its shape and original condition in temperatures ranging between -50°C to 100°C

Design Capability

Depending on what your project is, the design capabilities of the material could potentially be another important factor to consider when choosing the right material for your build. One of the notable features of Expanded Polystyrene is that it can be moulded into basically any shape without threatening its long-term durability. Here at High Profile Architectural Mouldings, we use advanced computer-aided technology to precisely cut and shape all our EPS mouldings. This means its design capabilities are basically endless so if you can imagine it, we can create it using EPS. Plaster on the other hand cannot withstand elevated temperatures meaning there are big restrictions in terms of the types of metals that can be used in conjunction with the mould. Additionally, the process of moulding plaster is a lot more difficult compared to EPS which results in a higher cost for a finished product.

If you would like to learn more about how our polystyrene mouldings can transform your home or help you bring that unique creative vision to life, contact us today on 07 5568 0036 or email us at info@highprofilemouldings.com.au. Whether you would like advice on how we can best help you in building a unique look for your home or start planning your next project the team High Profile Architectural Mouldings can help.